Today, businesses are looking for ways to reduce energy usage and utilize technology to produce energy in a sustainable manner. In this article, we’ll explore combined heat and power (CHP), explaining this concept, how the process works and what types of businesses will benefit by implementing this process.

What is CHP?

CHP, also known as cogeneration, is a process by which both electricity and thermal energy are produced from a single primary energy source, such as natural gas. The process can replace, or supplement electricity provided by your local utility and fuel burned in an on-site boiler or furnace.

This process is one of the most efficient ways for businesses to improve their energy efficiency, reduce their greenhouse gas emissions, lower their operational costs and encourage independent sustainability.

CHP plants with natural gas-fueled generators have delivered substantial benefits for many years. In Europe and North America, such plants provide cost effective electricity and heating in numerous commercial settings. In Asia and in other developing countries, CHP plants provide a steady source of electricity where utility power reliability and quality are inconsistent, while also delivering heat for process industries to help drive economic growth.

CHP is an important electric generating resource in the United States. In 2018, there were over 4,000 commercial and industrial CHP sites in the U.S. with a total capacity of over 80 gigawatts.

History of CHP

The CHP process originated in the 1880s when many industries in Europe and the United States used their own coal-fired generators to produce electricity that powered their mills, factories or mines. The steam produced from these generators also provided a byproduct used as thermal energy for various industrial processes or to heat certain spaces. In 1882, Thomas Edison built the first commercial cogeneration power plant in New York City. While steam engines in the plant produced electricity, the thermal steam byproduct was distributed to local manufacturers and used to warm nearby buildings.

How does CHP work?

A conventional power plant makes electricity using a fairly inefficient process. A fossil fuel such as oil, coal or natural gas is burned in a giant furnace to release heat energy. The heat can be used to boil water and make steam. The steam can drive the turbine which drives the generator to produce electricity.

The energy that is produced is wasted in every step of the process. For example, the water that is boiled into steam to drive the steam turbines needs to be cooled back down using giant cooling towers in the open air, casting energy. Rather than allowing the heat to escape from the cooling towers, the heat or thermal energy can be recovered as steam or hot water and used to meet on-site heating requirements. This concept is the basis for CHP, capturing heat that would normally be wasted in electricity generation thus using this byproduct for heating purposes. CHP plants can potentially reach overall efficiencies of 65 to 85 percent, compared to 45 to 55 percent for most conventional plants. Please note that plant efficiencies can vary depending on site-specific parameters.

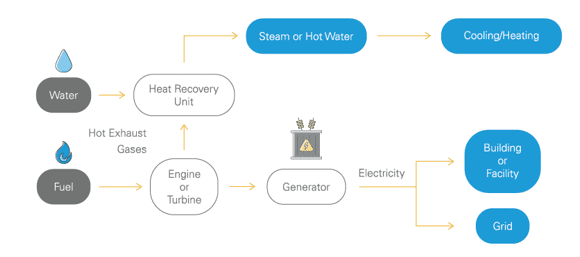

A common CHP application is shown in the diagram below. Gas or liquid fuel is combusted in a prime-mover piece of equipment, such as a gas turbine or reciprocating engine. The prime mover is connected to a generator that produces electricity. Energy that is normally lost in the prime-mover’s hot exhaust and cooling system is recovered to provide thermal energy for the site.

Source: ACHR News

Advances in technology have resulted in a wide variety of cogeneration applications. Today, cogeneration can produce more than just the traditional outputs of electricity and hot water or steam. Usable engine outputs can also include:

- Heated air. Steam or hot water can be passed through heat exchangers to create hot air to feed equipment such as kilns and grain dryers.

- Chilled water. Steam, hot water or exhaust can be passed through absorption chillers to produce cold water for space or process cooling.

- Carbon dioxide (CO2). Engine exhaust rich in CO2 can be purified in a catalyst reactor, cooled and then fed to a processer. Applications include fertilizer, industrial chemical production and carbonation in soft drink bottling.

Advantages and disadvantages of CHP cogeneration

In addition to the efficiency advantages of CHP previously discussed, there are also environmental benefits associated with the process. Every ton of fossil fuel not burned stops carbon monoxide from entering the atmosphere. Burning less fossil fuels also reduces air pollution. Replacing large power plants with more CHP plants that are sized for individual sites results in less dependency on a centralized energy network, which can lead to fewer major system failures and outages (blackouts). Just like conventional power plants, CHP plants can run with virtually any fuel from oil and natural gas to methane gas that’s produced in landfills.

There are several financial advantages that come with cogeneration. On-site energy and heating costs can be significantly reduced, especially with regards to those systems that use captured heat to manage the temperatures in your building. Higher operating efficient CHP systems consume up to 40 percent less fuel while generating the same amount of power and thermal energy as separate heat and power systems. CHP systems also provide long-term price certainty and can act as a hedge against increasing electricity costs, including capacity and transmission costs, as well as help manage energy purchases from the market during on-peak hours.

Cogeneration is considered a secure power supply since it provides stand-alone power that isn’t dependent on the power grid. By using cogeneration your business can operate off-grid or easily supplement your power needs to meet a surge in power demands, making your business resilient.

A disadvantage to CHP is that the technology is complex, so there can be challenges in implementing the solution, as well as initial capital investment and ongoing maintenance and management of the system. These tasks can sometimes consume internal resources, which may have cascading implications with your organization. You can avoid the upfront capital expense by financing the investment under a Power Purchase Agreement (PPA) by committing to electric and thermal energy purchases under a medium-to long-term agreement with an energy solution provider and investor, such as OnSite Partners.

Applications

CHP is ideal for businesses that have steady thermal and electric loads. Some examples include:

- Industrial: chemical plants, refineries, pulp and paper mills and food processing sites.

- Commercial: hospitals, nursing homes, hotels and health clubs.

- Institutional and Residential: universities, military bases, prisons and multi-family dwellings.

A common misconception of CHP projects is that they are only cost-effective for large industrial users that need large volumes of steam. Commercial customers with large hot water demand such as restaurants, hotels and nursing homes can also secure cost savings.

Is my facility a candidate for CHP?

Your facility may be a good candidate for CHP if you answer “yes” to any of these questions:

- Are you concerned about the impact of current or future energy costs on your business?

- Are you concerned about the reliability of your facility’s electrical supply? Would there be substantial business, safety or health impacts if electricity supply is interrupted?

- Do you have thermal loads throughout the year, such as steam, hot water, chilled water or hot air?

- If you already own on-site energy equipment, do you expect to replace, upgrade or retrofit central plant equipment, such as generators, boilers and/or chillers, within the next three to five years?

- Are you interested in reducing your facility’s impact on the environment?

Moving forward

Commercial and industrial facilities, institutions, food processing facilities and other businesses with both electric and thermal energy demands are increasingly considering CHP systems, in particular gas-fueled systems, based on current market conditions and considering today’s CHP technology. A CHP solution can help businesses stabilize their future energy costs, reduce their carbon footprint and achieve corporate sustainability goals.

Interested in learning more?

OnSite Partners have helped many businesses evaluate and implement clean energy solutions that create stability for the future of their organizations.

If you’ve found this blog informative and would like to learn more, please contact us online.